Pre filled Syringe Filling & Stoppering Machine Manufacturers in India

Pre Filled Syringe Filling Machine

- Compact machine / Dosing of syringes in nests from 0.2 to 20 ml.

- Ready-to-use disposable syringes offer ease of use, security, hygiene and dosing accuracy for medical injections.

- Our line allows a combination of filling closing for processing ready-to-use disposable syringes and vials in nests.

- Ready-to-use disposable syringes are supplied sterilized and ready to-fill into trays called “Nest”.

- The equipment is designed to be used in sterile room applications, in accordance with regulations of the cGMP and USFDA.

- Machine adjusted automatically and are associated to each format of syringe or vial processing.

- The formats can be recalled from the control panel, re-establishing automatically the ideal predetermined settings.

- New programs can be created easily and quickly by the user.

- The changeover to a different size is carried out quickly, easily and without tools, by exchanging complete sets of format parts.

- To work under sterile room applications we offer different laminar flow units enclosures adapted to each size of machine.

- These optionals guarantee to work under ISO 5 Class.

- The unit can be designed to be installed into an isolator when production requirements recommend its use.

Features :

- Robotic Tyvek Removal System.

- Semi-Automatic & Fully Automatic Machines Option Available.

In Compliance with :

- cGMP

- GAMP

- 21 CFR PART 11

Machine sequence of operations :

- Manual or automatic insertion and manual or automatic removal of “Nest”, depending on the machine model.

- Dosing through valveless rotary piston pumps or through peristaltic pumps.

- Automatic infeed and automatic positioning of plunger stoppers / stoppers.

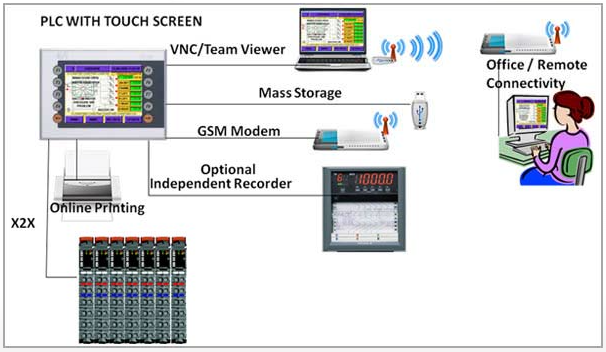

Automation:

All production parameters are stored in the PLC data memory, through “formats”.Therefore, parameters such as :

- Dose volume.

- Programmable Kinematics of the filling process.

- Positioning depth of the plunger stoppers / stoppers.

- Output speed.