Stainless Steel Mixing Tank Manufacturers in India

Injectable Manufacturing Vessel

The injectable manufacturing vessel is used for the pharmaceutical preparation of injectable liquids. Neelam Industries manufactures & supplies this product with features that are required in Pharmaceutical cGMP requirements. The small-volume parenteral manufacturing vessel has a dish end at the top and bottom of the Shell and having no corners for zero chances of contamination. It has proper connections and nozzles offered on the top & bottom of dishes depending on the industry requirements. We are a Sterile mixing vessel manufacturer who manufacture vessels as per the industry guidelines. It has a fully automatic touchscreen base control panel with CIP & SIP system which also makes the operation smoother and reliable. At the Bottom of the vessel a low shear magnetic stirrer and high shear magnetic stirrer mounted for the hygenic mixing of product.

Our Injectable Manufacturing Vessel has a cutting-edge design that caters to the specific requirements of pharmaceutical and biotech industries. We manufactures our different types of sterilizers that includes steam, air mixture sterilizers and many other sterilizers made from high quality material that ultimately gives exceptional performance.

Main Applications:

- Sterile Solutions & Vial

- I. V. Fluids & Serums

- Ampoules

- Bacteria and cell cultures

- LVP & SVP Solutions

- I. V. Fluids & Vaccines

- Human Insulin Programs (CIP & SIP Cycle)

- Leak Test Cycle

- Product filtration & Manufacturing Cycle

Technical Specification:

- It has a mounted magnetic mixer (speed variation from 20 to 350 RPM)

- Flush bottom outlet value & pH sensing

- Conductivity & temperature sensing

- For weight measurement, it has Load Cells

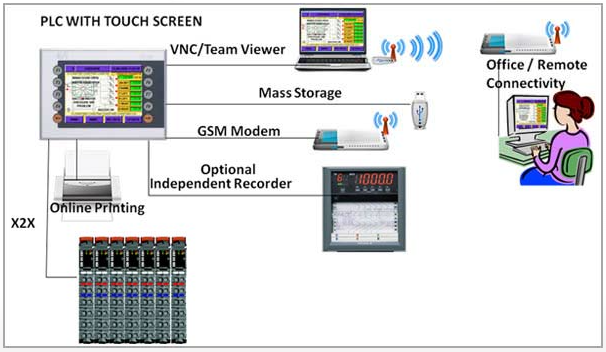

- Auto printing and remote Support Facility

- 21 CFR PART 11 Compliance

- Vessels are manufactured under the guidelines of ASME & BPE Guidelines.

FEATURES :

- The chamber is fully welded, and there is no leakage to insulation occurs

- The chamber is easy to maintain and clean

- The highest temperature HEPA filters are installed in the inlet & exhaust sides of DHS.

- We install HEPA filters inside the chamber, which is equipped with the full height & depth of temperature.

- Sizes are available from 10 ltr. to 10000 ltr.

- It is available in huge options for connection with mobile SIP and CIP skid

- It can mix till the last drop

- Options are available for the top-entry mechanical stirrer

- Low shear & high shear magnetic stirrer for oil base products

- Magnetically powered drive with no seals and shafts

Automation: