Pharmaceutical steam Sterilizer

High Shear Magnetic Stirrer Manufacturer in India

Magnetic Stirrer

The magnetic stirrer, also referred to as magnetic stir, is used in the sterile Pharmaceutical plant to Mix Injectable liquid. The magnetic stirrer Impeller allows proper mixing of Injectable Liquid.

Neelam Industries offers a wide range of manufacturing Magnetic Stirrer exporters with High shear and Low shear Magnetic Impeller.

The magnetic mixer transmits the required torque by means of magnetic coupling.

The magnetic coupling consists of two sets of permanent magnets and a weld plate that separates the magnet sets.

Our Magnetic Stirrers are well known for their precision, efficiency, and innovation, suitable for all kind of scientific and industrial uses. As a trusted Magnetic Stirrer exporter, we take pride in supplying and manufacturing top-quality machinery that delievers optimum results.

Applications of Magnetic Stirrer:

Pharmaceuticals

- Sterile Solutions

- Vial

- Ampoules

- I. V. Fluids

- Aerosols

- LVP & SVP Solutions

Biopharmaceuticals

- Vaccines

- Human Insulin

- Serums

- Plasma Fractions

- Bacteria and cell cultures

Magnetic Stirrer

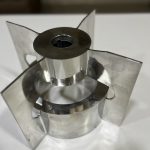

High Shear Magnetic Stirrer

Features of Magnetic Stirrer :

- Cost Effective solution for complete range of sterile liquid products

- Its a unique impeller design enables effective mixing right down to the last drop

- Magnetically powered drive, no seals, no shafts, thereby eliminating possibility of contamination

- Low Power Consumption compared to conventional agitation systems

- Ability to mix till the last drop

- Low Shear Forces (less damage to product)

- The magnetic mixer range offers unparalleled hygiene due to its impeller design. Because there are no entrapment areas, the magnetic mixer can be completely drained of product and cleaning solutions. The open design also ensures full coverage by the cleaning solution and contributes to efficient removal of product residues. The lack of friction also minimizes product contamination from wear particles.

- Low Shear Forces (less damage to product)

- The unique impeller design allows the mixer to operate under dry conditions. The impeller design eliminates friction, making it possible to mix at velocities ranging from 10 to 600 rpm

CAPACITY :

Processing Batch sizes from 5 litres to 30000 litres

WORKING PRINIPAL OF MAGNETIC STIRRER :

The magnetic mixer transmits the required torque by means of magnetic coupling. The magnetic coupling consists of two sets of permanent magnets and a weld plate that separates the magnet sets.

One set of magnets is mounted in the impeller and the other set in the rotor. When the rotor revolves by means of the gear drive, the interaction between the two sets of magnets creates a magnetic field, which causes the rotation of the impeller. To avoid loss of magnetic coupling, it is necessary to gradually ramp up the rotation by means of a frequency inverter.

The typical ramp up time is approximately 30 seconds. The frequency inverter is also used to adjust agitation intensity as necessary.

Since the weld plate transmits the magnetic field across an air gap, the tank is not compromised and therefore does not require a seal. This eliminates the risk of leakage and product contamination.

The unique design of the Neelam Industries, magnetic coupling ensures the levitation of the impeller at all time. This enables the complete drainability of process fluids and the free flow of CIP liquid and steam around all parts of the mixer, thereby ensuring thorough cleaning.