Rubber Bung Processor Cum Steam Sterilizer Manufacturer in India

RUBBER BUNG PROCESSOR CUM STEAM STERILIZER

Are you looking for a cutting-edge solution to smoothly run your industrial processes and ensure the highest level of product quality and safety? Look no further! Our Bung Processor cum Steam Sterilizer is the answer to your needs. This innovative Sterilizer machinery of equipment is made to meet the stringent requirements of different industries while offering exceptional efficiency, convenience, and safety.

A Bung Processor cum Steam Sterilizer is a specialized pharmaceutical machinery like other sterilizers including terminal sterilizer supplier, air mixture sterilizer exporter, and many more. It combines the technology of bung processing and steam sterilization. It is primarily used in industries such as pharmaceuticals, food and beverage, and biotechnology, where maintaining a sterile

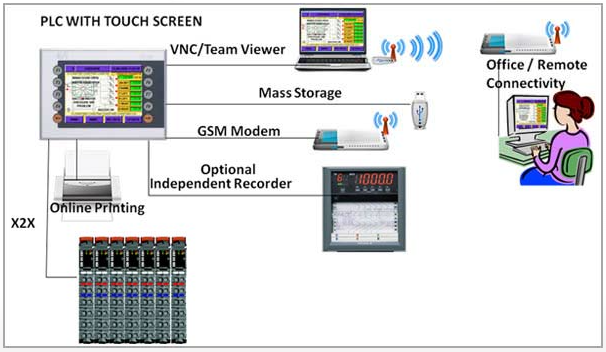

Rubber bung processor cum sterilizer enables customers to unlock the benefits of twin processes from a single machine. The bung processing steps include loading, washing, rinsing, sterilization, siliconization, and drying. The bungs are loaded into the drum & After completion of Bung washing / rubber stopper washing process sterilization process starts. The complete procedure is done via PLC, and final sterilization is done through the HPHV cycle. Neelam Industries has designed a unique rubber bung sterilizer with the aim of providing enhanced results. We manufacture & supply these products to various industries in real-time.

Programs :

- 1) Rubber Stopper Washing and Sterilization Cycle

- 2) Fast exhaust cycle

- 3) Slow exhaust cycle

- 4) HPHV Cycle

- 5) Chamber leak Cycle

- 6) Bowie Dick test Cycle

USP:

- 1) Dimple Steam Jacket for Uniform

- 2) Heat Distribution.

- 3) Inflatable Door Gasket for Sliding Door.

- 4) Online Cond. Sensor for Bung Washing.

FEATURES :

- The sterilizer ensures easy & smooth loading/unloading of closures

- There is a special arrangement of baffles that ensures uniform air distribution inside the chamber.

- PLC-based control panel with auto-controlling panels.

- For quick-drying rubber stoppers, there is a specially designed compact unit.

- Expandable Silicone door gasket for zero leakage while operating

- After operation, the stoppers are unloaded to the sterile area

- For checking the wash quality of the closure, an online conductivity sensor is installed

- The rectangular chamber is designed with highly finished AISI 316L stainless steel.

- Pressure is monitored within the chamber through a pressure transmitter

- Automated dosage of detergent & silicon

- Single/double door with hinged & sliding door options.

- Touch screen & auto printing facility

- Temperature sensors & validation ports are installed.

- The trolley is designed in such a way that it can be easily loaded and unloaded.

Automation:

Main applications:

- For washing, sterilizing, and siliconisation of rubber stoppers

- Inox instruments & equipment

- Empty containers & glassware

Inox machine parts - In the manufacturing of accessories & filters

- It is used in plastic materials

- Liquid solutions

Request a quote