Clean in Place (Cip) and Sterilize in Place (Sip) Systems Manufacturer in India

CIP System

Neelam Industries’ CIP & SIP System is tailor made system which is used for Cleaning & Sterilizing the precious machines and equipments to avoid down time.

It consists of a Stainless steel 316 Vessel, recirculating pump, SS 316 corrugated flexible hose pipe with all necessary accessories.

Neelam Industries cleaning in place ( CIP ), and sterilization in place( SIP ) technologies are implemented to ensure a clean and sterilized condition.

Advantages

- Validation process for sterilization of process

- equipment Lower facility operating costs.

- Minimal dismantling of equipment and piping.

- Process vessels need not be autoclaved.

In Compliance with :

- cGMP

- GAMP

- 21 CFR PART 11

Technical Specification

- Completely Automated Process Cycles

- On line display of process parameters with P & I of Operating Systems

- Display of Fault messages

- Supervisory access code prevent unauthorized changes

- Detergent / Acid / Alkali dosing

- On Line pH, Conductivity, TOC Sensing

- Single tank system to multi-tank systems

- Flow range 1.0 m3/hr to 50.0 m3/hr

- 50 Ltrs to 3000 Ltrs Stainless Steel 316L makeup /recirculating tank

- CIP & SIP System is designed in accordance with ASME BPE and EHEDG guidelines

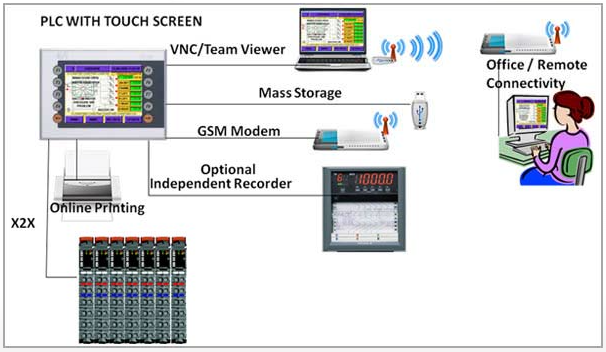

- PLC-based, with Touch Screen MMI and SCADA Packages

Automation:

FEATURES :

- Lower Facility Operating Costs

- Minimal dismantling of equipment and piping

- Reduced turn around time for cleaning

- WFI requirement for cleaning reduced significantly

- Exposure to hazardous activities or entry into tanks, is eliminated

- Why Choose our CIP SIP System, Clean in Place, Sterilization in Place

- CIP and SIP system comes with optimum configuration, which ensures the high flow velocity and flow rate.

- The specially-designed low energy spray can wet the surface completely.

- Minimize downtime between product runs and product changeover.

- CIP and SIP system adopts common cleaning media like caustic, acid, disinfectant, return water, fresh water, and steam for SIP, resulting in reduced running costs.

- Customized CIP and SIP system are also available upon request.