Sterilization and Depyrogenation Tunnel Manufacturer in India

Depyrogenation Tunnel

Are you in search of a premier Depyrogenation Tunnel Manufacturer? Look no further than Neelam Industries. Our dedicated manufacturers are committed to provide you with the best sterilizers including dry heat sterilizer manufacturer, Steam Sterilizer manufacturer, sterile mixing vessel manufacturer, etc in the industry. Our Depyrogenation Tunnels are a testament to our innovation and expertise.

Depyrogenation is the crucial process of removing pyrogens, which are fever-inducing substances, from various equipment, primarily in pharmaceutical and biotech industries. Our Depyrogenation Tunnels play a vital role in ensuring the safety and integrity of the products we manufacture.

The depyrogenation & sterilizing tunnel utilizes hot air to ensure that the sterilization of the vials is carried out in the best possible way. Our team of Neelam Industries has expertise in the industry of depyrogenation tunnel manufacturers. Pharmaceutical companies have huge requirements for Depyrogenation of Ampoules and Vials. It is used for depyrogenation of ampoules and vials before fill and seal of vials and ampoules. Neelam Industries manufactures fully automated systems that are specifically used to wash and Depyrogenation empty ampoules and vial pharmaceutical glassware, which is used for parenteral product packaging. The Depyrogenation sterilization cycle depends on the selection of cycle time & the temperature exposure.

Features of Depyrogenation Tunnel:

- Individuals can monitor the conveyor belt.

- The independent filter is compiled with the filter integrity.

- The ports have been installed that allow the entrance of validation thermocouples in each zone.

- In case the belt operates beyond the speed limit allowed at a certain point in time, then an alarm will be triggered.

- For monitoring the alarms, there is a pressure switch.

- The tunnel has been equipped with an advanced vial controller.

- Every filter module contains a magnehelic gauge, which has been installed to track the pressure.

- The tunnel has an integrated night mode, which is used for saving electricity. Night mode is used to ensure that the contamination is averted when the machine is not used.

- For tracking and controlling the temperature, integrated temperature sensors are installed. Here, one sensor is installed above the HEPA filter, and others are installed in the sterilizing zone.

- Multiple pressure gauges are installed for tracking the pressure drop across HEPA filters.

- The entry & exit of the sterilizing zone has manual & auto adjustable profile plates, which results in maximum uniformity temperature.

Main Applications :

- For sterilization & depyrogenation of Ampoules and Vials

In Compliance with :

- cGMP

- GAMP

- ISO 9001: 2008

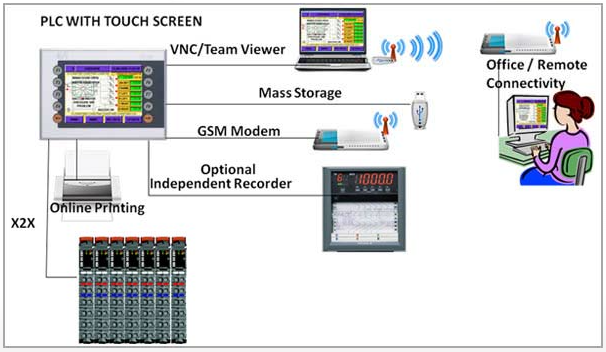

Automation: