Fermentation Vessels Manufacturer in India

FERMENTATION VESSELS

Fermentation Vessels manufactured by Neelam industries are the most flexible designed product to meet the requirements of the Pharmaceutical Industry.

Fermentation Vessels

Technical Specifications

- Capacity : 4-5 KL

- Filling Volume : 65-80%

- Material : Wetted parts are SS316L, and others is SS304

- Surface Finish : inside surface is 0.28-0.6µm by electro Poloshoutside surface is 0.4-0.8µm by satin finish.

- Agitation

- Fermentor use SEW / Bonfigloli decelerator

- top mechanical agitator with two layer six blade impeller, one layer defoamer and four baffles.

- mechanical seal (single or double mechanical seal)

- speed range: 50-400rpm (it depends on the size of the vessel)

Or

Bottom mounted Magnetic mixer with speed variation from 20 to 400 RPM

- Equips of vessel

- using alcohol flame inoculation

- sterilisable sampling and Flush bottom valve

- CIP & SIP system inbuilt.

- PH, DO, temp. sensor on lower side, side glass, top with foam and level probe, and 12v sight glass with lamp, etc.

- Construction : Floor-type One fermentor vessel with one control system

Main components and controls of system

- PH :

- On-line check and measure, and digitization fully automatic control

- PH, acid and base gang control. Peristatic pump automatically adjust to feed acid and base

- Control range 2-12pH, measure precision±0.01 pH, control precision±0.1 pH

- It has auto alarm function

- pH sensor and signal transmission line, Mettler toledo

- Do :

- On-line check and measure, cascade with rpm; digital display.

- Range 0-100% or 0-200%, precision ±1%;

- It has auto alarm function

- DO sensor and signal transmission line, Mettler toledo

- Foam control :

- Automatically control and automatically alarm

- Stainless steel electrode check, peristaltic pump automatically add defoamer.

- Feed control :

- Automatically control and automatically alarm

- Stainless steel electrode check, peristaltic pump automatically feeding

- Temp. control :

- PID fully digitization signal processing, digitization control settings

- Circulating water automatically control temperature

- Measure range 0-150degree, control range 15- 45degree,control precision±0.2degree

- Pt 100 O temp. Sensor

- system with electrical heater to control the temp inside vessel

- water pump circulation

- solenoid valve to control

- Rotate speed :

- Automatically control , with auto alarm function

- Siemens frequency converter to adjust the speed

- Pressure :

- Manually adjusting with pressure gauge and manual valve (standard system)

- Automatically adjusting with pressure transmitter and PID valve and pneumatic valves (optional)

- Air flow :

- Manually adjusting with rotor meter and manual valve (standard system)

- Automatically adjusting with mass-flow meter and pneumatic valves (optional)

- Air in filter , tail gas filter , with PALL cartridge, precision 0.2µm

- Sterilization :

- Fermentation vessel can be SIP by connecting with steam

- Automatic control with pneumatic valves

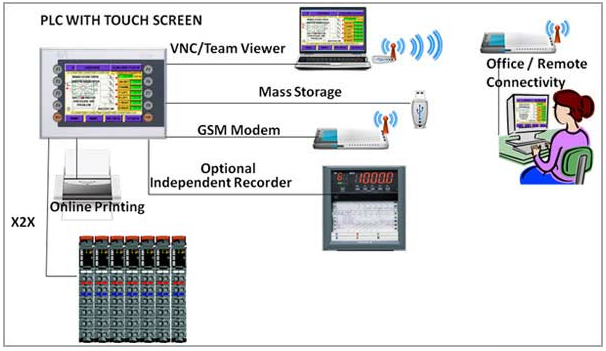

- Control : B&R AUSTRIA PLC, and B&R 10.4” touch screen(HMI) and NEELAM INDUSTRIES program

AUTOMATION :

In compliance with :

cGMP, GAMP, ISO 9001 : 2008